The continuous process remains uncommon in the area of industrial vinegar production, even though it is a very simply process that requires little from the processing technology. This is because it is not possible to realize high concentrations of acetic acid with this process (max. 9%).

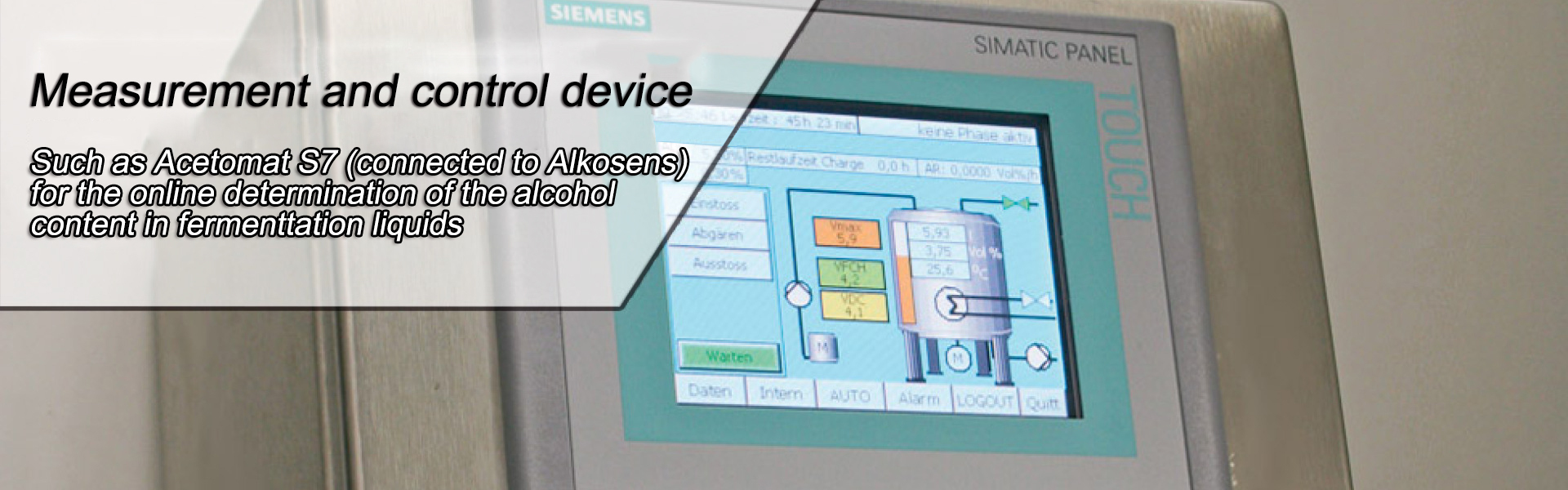

In technical-processing terms, it differs significantly from the charging processes as the concentrations of acetic acid, alcohol and other parameters remain constant during the complete fermentation phase (which can total several weeks and months). The continuous feeding in of the mash and the simultaneous removal of a volume flow with the same pumping rate lead to this so-called 'steady state'. The feeding in rate is set so that a low alcohol concentration of 0.3% and a maximum corresponding acetic acid concentration (depending on the alcohol content of the mash/of the wine) occurs in the fermenter. Variations in the activity of the acetic acid bacteria or the mash concentration are counterbalanced using a control system, consisting of an online ethanol probe and a controller.

The process is especially suited to producing vinegar from low percentage wines or mashes, the alcohol content of which is limited for quality reasons or operational reasons.

Storage of vinegar in Barrique barrels