In order to provide the highest level of quality and flexibility in the manufacture and assembly of our machinery and equipment we carry out all of the work in our own workshops. Our manufacturing workshop is equipped with all machines and processes which are required for the manufacturing of high quality stainless steel plants. This includes: cutting, sheet processing and frame construction, different other processing centres, lathes, boring machines, welding unit with automated welding robots and mobile welding machines, grinding and polishing places, cleaning and pickling plant, balancing centre and preassembling area.

All matters relating to the manufacturing and the assembly procedures are planned, realized and controlled by computer using the PPS system. Due to the written audit trail made for each individual piece, we generate clear documentation even for the more complex material combinations. This permits us to manufacture according to GMP standards.

Particularly in the fields of vinegar technology and environmental technology we employ a large number of corrosion resistant components and high quality plastic components.

For the final assembly of semi-finished plastic products we have our own dedicated workspace. Here we carry out the cutting, chipping and assembling procedures of the different components and pipe elements according to precise design requirements.

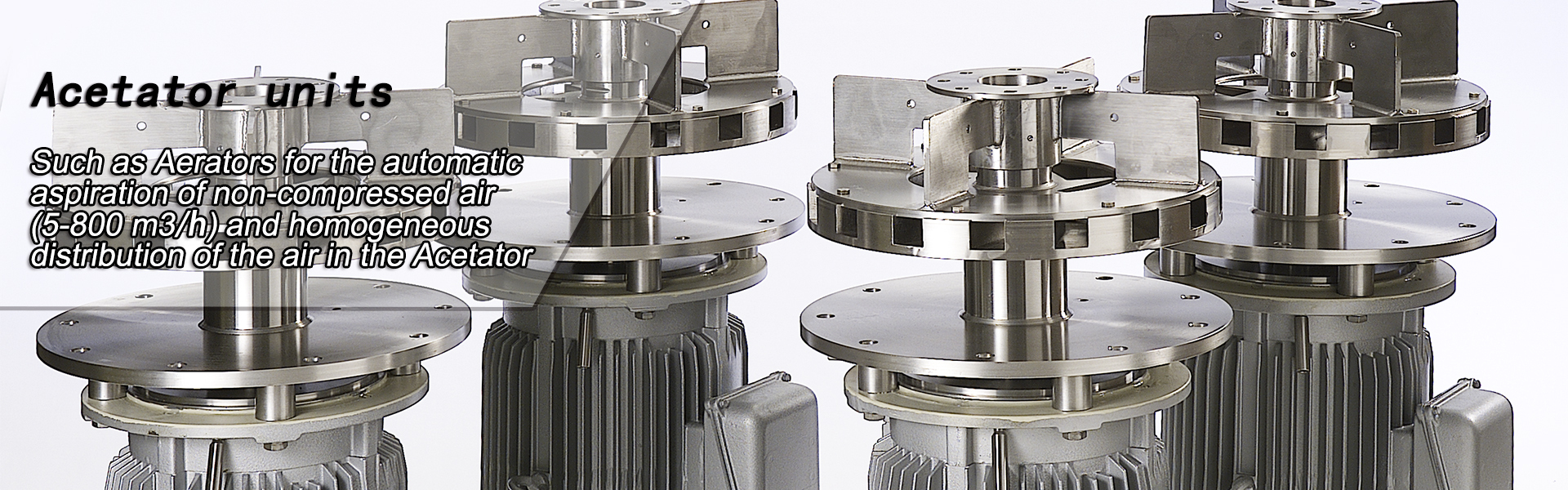

Presentation of the manufacturing details of one machine part (FOAMEX)

Presentation of the manufacturing details of one machine part (FOAMEX)

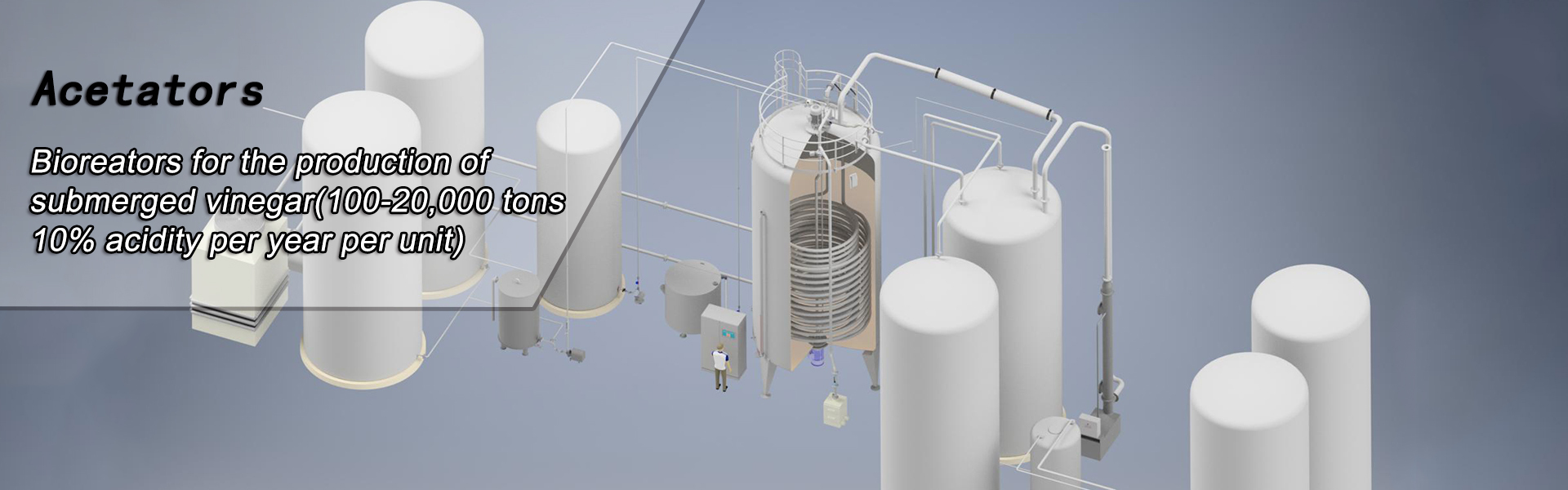

Fermentation plant in the assembling workshop

Fermentation plant in the assembling workshop

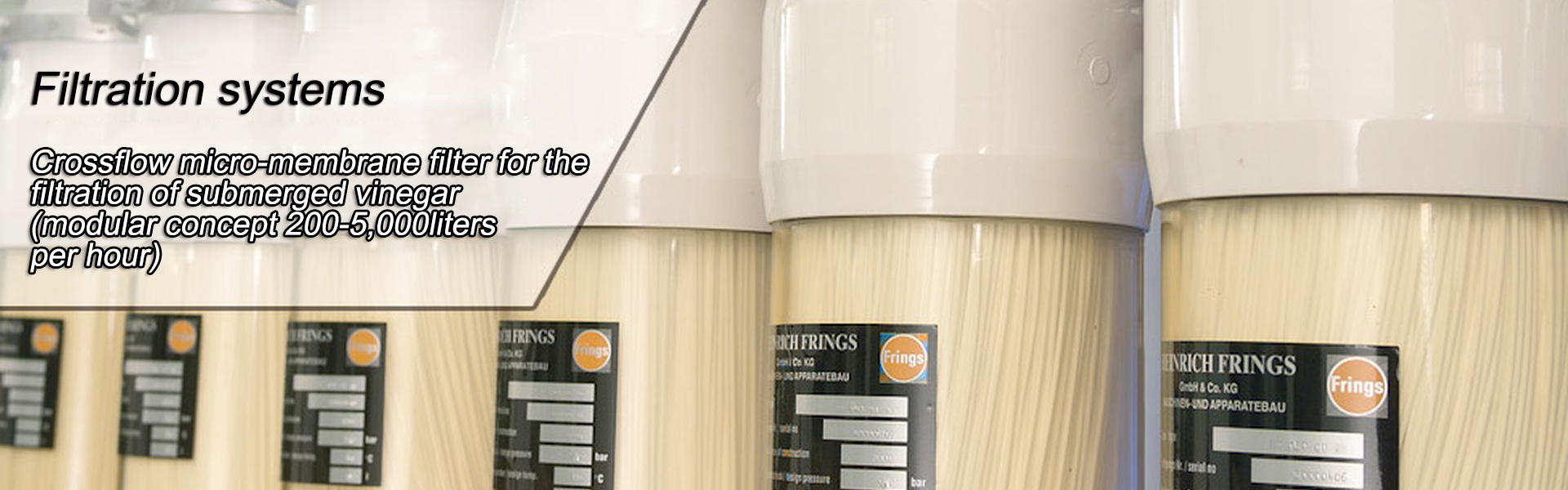

Filtration plant in the assembling workshop

Filtration plant in the assembling workshop