Whilst in the standard process it is possible to produce vinegar with a maximum acidity of 14.5%, the 'Single stage, high percentage fermentation process' (SSHS) developed by FRINGS permits the production of alcohol vinegar with an acidity of up to and exceeding 20.0%.

The SSHS process is based on the basic principle of the standard process (link to standard process). Like the standard process, it is also characterized by the periodic succession of batches, in which the concentration of alcohol falls and the concentration of vinegar increases until the target concentration is achieved. In the SSHS process, however, after the 'charging' phase and a fermentation phase known as the 'start of fermentation', another phase is also characteristic. During this phase, which is called the 'elevated' phase, highly concentrated alcohol is added separately, during which the alcohol concentration is also controlled at a constant level. During this phase, the concentration of acetic acid due to the conversion of the alcohol increases significantly. In the following 'fermentation' phase, the addition is stopped, the alcohol remaining in the fermenter is converted into acetic acid, and on reaching the 'discharge' alcohol concentration, the finished raw material is drained off. As with the standard process, a residual volume remains in the ACETATOR with an active biomass. During the 'charging' within the next charge, water, alcohol and nutrients are then pumped in and the aforementioned cycle begins again.

The SSHS process is accordingly divided into five successive process steps:

1. Charging

2. Start of fermentation

3. Elevation (increase of total concentration, TC up)

4. Fermentation

5. Discharge

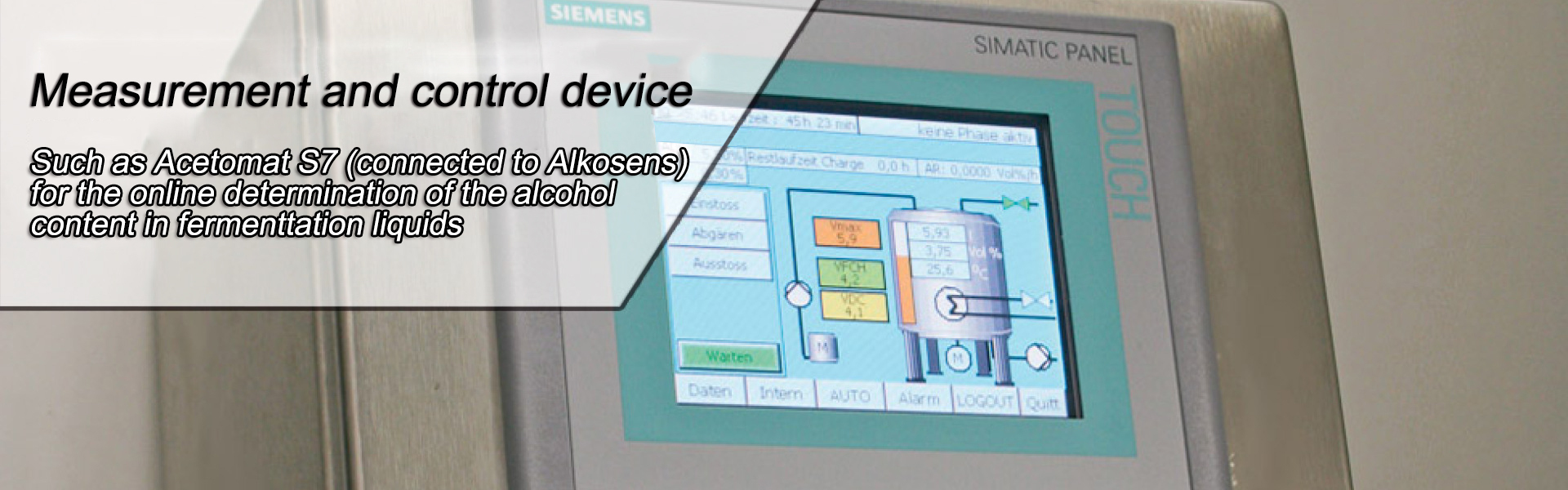

All of the control systems, sequences for the individual process phases and also the formulation calculations are programmed in the ACETATOR controls and are completed automatically. Although it concerns a complex process, the required operator intervention is minimal and the successive charges are carried out on a quasi continual basis over several months.

An additional process for the production of high acidity strengths is the DSHS-process. This is used in special cases if acidity strengths that are even higher than those in the SSHS process are to be attained. The key point of this sophisticated mechanical and technical process is the linking together of two ACETATOR Fermenters to create one functional unit. The first fermenter, the so-called donor ACETATOR, works in a comparable way to the one in the 1HP process, although the 'discharge' concentration is significantly higher. The 'discharge' volume is transferred to the second fermenter, the acceptor ACETATOR. Alcohol is then added in an additional 'elevated phase' and the alcohol is only 'fermented away' afterwards. In contrast to the donor, at the end of the following 'fermenting phase', the acceptor is completely emptied and cleaned. The biomass necessary for the biological conversion process of alcohol into acetic acid is transferred with the 'discharge' volume from the donor to the acceptor in every charge.

The procedure in both the SSHS process and the DSHS process is known as a 'Repeated-Fed-Batch Process'.

View in an ACETATOR (photo made during charging of mash at a spirit vinegar fermentation)

View in an ACETATOR (photo made during charging of mash at a spirit vinegar fermentation)